Are you planning to get into the fertilizer industry? Today I will introduce you to the top 3 commercial fertilizer production plans that are most likely to achieve huge economic benefits in 2025. They are commercial manure compost fertilizer production plan, bb fertilizer production projects, and roller-extrusion fertilizer granulation plans. You can choose according to your budget. Welcome to consult!

Top1: Starting low-cost Manure compost fertilizer production plan

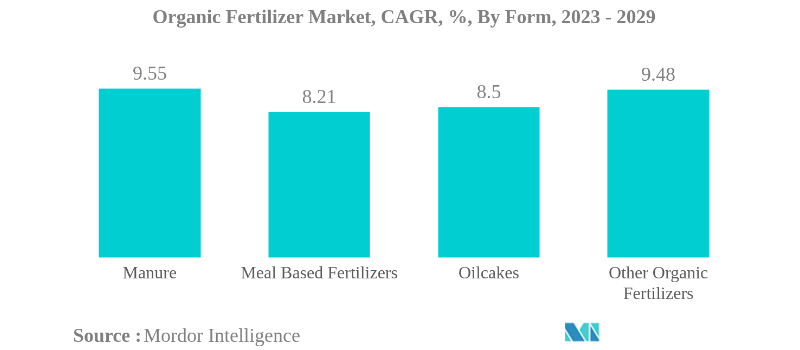

Why not to set up a manure compost fertilizer manufacturing plant? It is the most economic fertilizer production plan for organic fertilizer manufacturers. You can use animal manure, agriculture waste, plant residue to make organic compost. This can save raw material costs and at the same time, the fertilizer production equipment costs are lower. Moreover, according to reserach for the organic fertilizer market, the manure fertilizer market accounts for 45.3%. So, If you run a farm and want to deal with animal manure, you can choose to carry out a commercial fertilizer production plan.

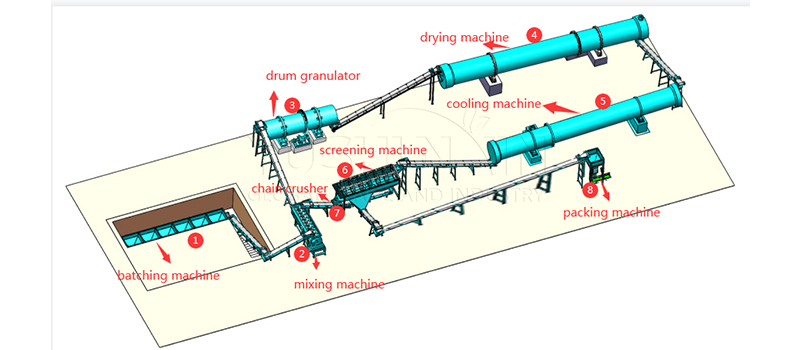

The process of making manure compost fertilizer is very simple. In manure compost fertilizer production plant, you should use compost turner, new type vertical crusher, drum screener, fertilizer granulation machine, fertilizer coating equipment, drum dryer and cooler, automatic bagging machine. You can customize the fertilizer production line according to capacity and demand. The production budget of powdered organic fertilizer is between $35,000 and $90,000, while granular organic fertilizer cost is about $110,000-$600,000.

Top 2: Setting up a Bulk blending fertilizer production line with fast return on costs:

The market prospects of making compound fertilizers are also bright. There is a large market demand for establishing a compound fertilizer production line. If you want to make a quick return on investment, you can choose to establish a bulk blending fertilizer production line.

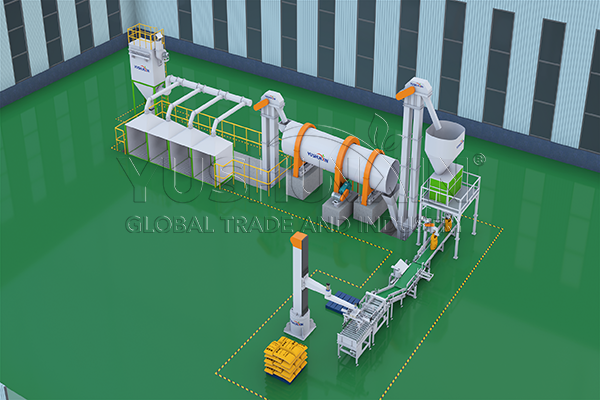

The production process of bulk blend fertilizer is simple and the production speed is fast. Generally, you need to use forklift feeders, dynamic batching machines, bb fertilizer mixers, screening machines, packaging machines, etc. Making bulk blending fertilizer mainly needs 3 steps. First, use the forklift feeders to feed chemcial fertilizer into dynamic batching machine according to a certain proportion. Then the bb fertilizer mixers will continously mix these raw material. After mixing, automatic fertilizer bagging machine will package the bulk blending fertilizer of different specifications for sale.

Top3: Establish A high-profit roller-compactor granulation line:

The fertilizer granulation line can bring you more profits. High-quality fertilizer granules are easy to store and transport. It is convenient for you to expand your fertilizer business.

Whether you want to produce manure compost biofertilizer granules or granular blend compound fertilizers, why not choose to start a double-roll granulation line? The roller-extrusion production line cost is about $160,000-$200,000. Double-roller press granulator can deal with the raw material of organic or compound fertilizer. It can achieve two birds with one stone. In additional, roller compoactor pelletizer adopts dry granulation method, it can help you save the drying and cooling cost. At the same time, you can use it to continuously produce fertilizer pellets.

The above are three commercial fertilizer production plans that are likely to make the most profit in 2025. If you want get the fertilizer production business plan, please contact YUSHUNXIN. We can provide you the suitable fertilizer making line for you according your needs.