In recent years, the Kenyan government has proactively implemented agricultural policies dedicated to improving crop yields, quality, and market competitiveness to achieve its goal of bumper harvests. On March 18th, 2024, a customer from Kenya sent us an inquiry. In this email, they said they want a double roller compactor to increase their bulk density of dry milled bagasse. In addition, they wanted the roller compactor granulator can produce bagassse granules over 1,000 kg per hour.

The detailed requirements for roller compactor granulator of Kenya customer.

At first, a customer from Kenya expressed their interest in our roller compactor granulator and they wanted an industrial machine to convert bagasse into denser granules with the bulk density of at least 350kg/m3. The company is looking for a robust compacting machine that can handle bagasse particles of 5mm or smaller. What’s more, they also mentioned that they need the roller compactor machine to produce granular bagasse with the size of 20mm. In addition, the production capacity they need is about 1,000 kg per hour.

Which equipment is suitable for 20mm granular bagasse production?

3-5mm Granules Making Machine.

Understanding the requirements of our Kenya customer, we proposed two types of granulating machine for them. Firstly, we suggested them to purchase a double roller extrusion granulator, which can hand materials with the size of 3-10mm. And depending on their demand for production, we offered them a flat die granulator. On the one hand, it can deal with materials at about 2-10mm. On the other hand, it can produce granular bagasse about 1-2.5 t/h. Both of the two granulating machine meet our customer’s needs. And finally, the customer chose our SXDG-1T of double roller extrusion granulator.

Auxiliary Equipment For Granular Bagasse Production.

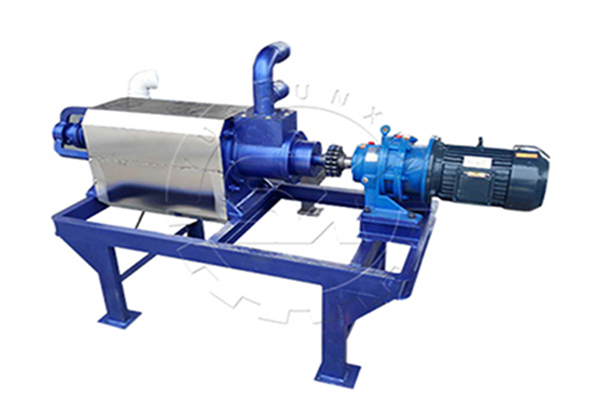

Considering their raw materials and the granulating machine they chose, we also advised they to buy a solid-liquid separator. It can reduce the moisture content quickly, which is beneficial to the processing of bagasse. What’s more, a dewatering machine can improve the quality of granular bagasse and reduce the damage to double roller extrusion machine. After taking our suggestion into consideration, they finally agreed with us.

How much does the Kenya customer cost?

Based on their specific requirements, we have proposed two granulating machines suitable for their bagasse pellet production. The two types of granulators we offer, namely the double roller extrusion machine and the flat die granulator, which are designed to meet their production needs effectively. The prices for the double roller extrusion machine available from our company ranges between $2,000 and $4,000, while the flat die granulator is priced between $2,000 and $6,000. In addition, the fertilizer dewatering machine is offered at a cost of $1,600 to $2,500. Taking into account both the machinery costs and the transportation expenses, the total investment they are looking at will fall within the $4,000 to $10,000 bracket.

After receiving the machinery, the client from Kenya arranged a visit to our factory to learn more details about products. Our company prepared a professional tour for them, showcasing the production process and provided training on operation and maintenance. The client expressed their great satisfaction with our service and products. In the end, we committed to providing ongoing technical support, strengthening the trust for future collaboration.