In recent years, Malaysia’s agricultural development focused on improving food safety, agricultural modernization, sustainability and productivity. In order to improve their crops yields and competitiveness, a customer from Malaysia contacted us on Feb. 26th, 2024 and wanted to purchase a fertilizer mixer. According to their demand, we recommended them a disc mixer. In addition, we also advised them some essential auxiliary machine, like fertilizer dewatering machine and fertilizer crushing machine.

What’s the main requirements for mixing machine of the Malaysia client?

The customer are seeking a high efficiency and durable fertilizer mixing machine that should meet the following several requirements. First of all, the fertilizer mixer need to handle a wide range of materials, including EFB, animal manure and zeolites. What matters most is that the mixer must be made of wear-resistant materials to cope with the abrasive nature of the material and the water content, while maintaining good performance and longevity. In addition, they also emphasized that the mixer they want can mix the materials evenly to produce uniform fertilizer. In a word, they need a multifunctional fertilizer mixer with high capacity production.

Which mixer machine we recommend them?

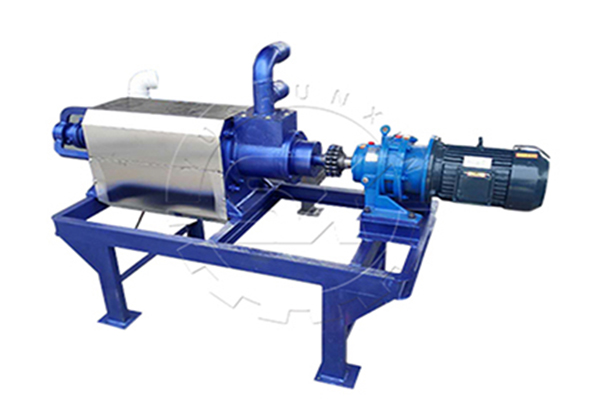

Based on their requirements, we suggested them a disc mixer, which has a wide application can produce different fertilizers. The disc mixer has a high abrasion and corrosion resistanceis that suits for converting highly corrosive materials into fertilizers. In addition, the disc mixing machine can mix materials efficiently and has a less occupied area. What’s more, the pan mixer can mix over 12t materials in an hour that is very suitable for large scale mixing. In a word, disc mixer meets for the Malaysia client better. Besides, we recommended them other auxiliary equipment like fertilizer dewatering machine and crushing machine. Combining the disc mixer with auxiliary machines makes it easier to produce large scales fertilizers. The dewatering machine is crucial for removing excess moisture, which is a key step for the next stage of production. And the crushing machine can crush the bulk material into smaller size and reduce damage.

What’s the total price of a fertilizer mixer and 2 auxiliary equipment?

The price of a fertilizer mixing machine vary significantly, typically falling within the $800 to $3,000. And this price variation often stems from differences in the machine’s production capacity and specific functionalities it offers. In the cases of a disc mixer that the Malaysia, the price was around $2,000, which reflects the features and efficiency it provides for their operations. What’s more, the combination between fertilizer mixer and auxiliary equipment ensures that our customer can handle raw materials more effectively and produce a consistent, high-quality fertilizer product. And the manure dewatering machine costs about $1,600~$2,500. A fertilizer vertical type crushing machine sells at $1,600~$2,000. In conclusion, including all the expense of mixing machine and the 2 auxiliary machines, the total expense is at $5,000~$7,000.