In modern agriculture, fertilizer is a key factor in improving the production and quality of crops. And in order to manage the use of fertilizer better, there comes fertilizer granulation line. It can convert powdered or liquid fertilizers into an easy-to-use granular form. This not only helps to distribute the fertilizer evenly, but also reduces dust and prevents separation of ingredients.

How to produce fertilizer?

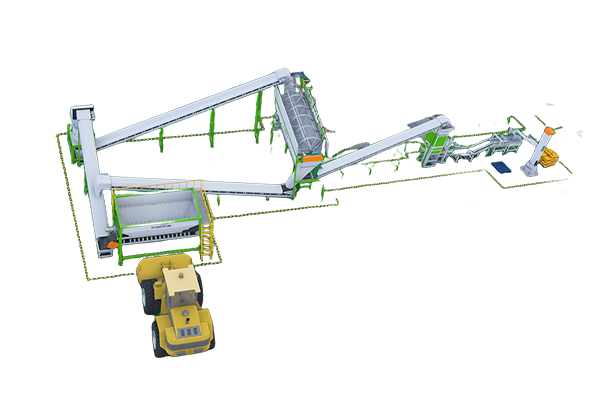

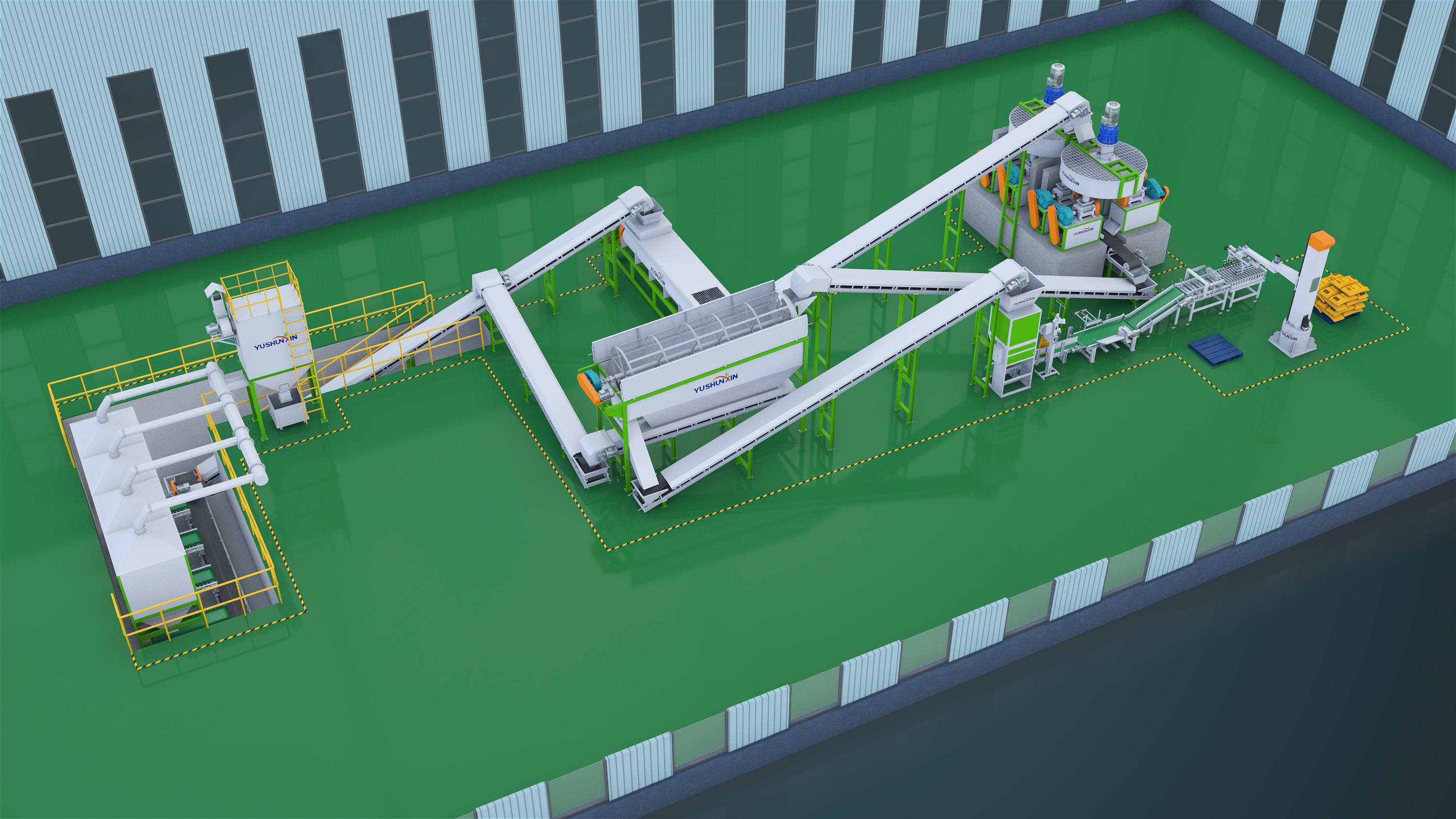

The process of fertilizer production mainly includes the steps of matching, stirring, granulating, drying, cooling and packaging. And though high efficiency, it can produce high quality fertilizer pellets that meets agricultural demands. And the following is the basic process of fertilizer granulation.

In this step, you need to put your materials together and match them according to specific fertilizer formulations. At the same, you can add some trace elements and additives and you had better be careful with their dosage. These materials are accurately fed into a fertilizer mixing machine in certain proportions. And it’s helpful to ensure the quality of the final product and the homogeneity of the nutrient content. And then you can stir them in a fertilizer mixing machine. That is helpful to ensure the even mixing of various materials.

After mixing the materials, you can put them into a granulating machine. There are different types of granulators for you to choose like rotary drum granulation plant, disc granulator, and double roller granulator. Depending on the equipment and technology chosen, materials can be pressed into spherical, cylindrical or other shapes. In this process, the material is subjected to mechanical pressure or a binder is added to aid in the bonding process to form strong pellets.

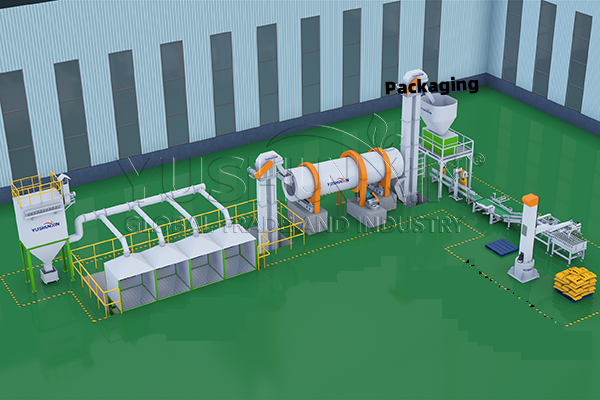

After granulation, the moisture content is higher which can not guarantee the quality of fertilizer. Therefore, you need to dry fertilizers and reduce the moisture content. The hot air oven provides the heat source for the dryer, which can reduce the moisture quickly and improve the working efficiency. And after drying, the belt conveyor will transport fertilizer to a rotary cooling machine. This is helpful to prevent particles from binding. After that, you can use a fertilizer packing line to packing fertilizers.

These are just the basic steps of producing fertilizers, you can do some adjustment according to actual requirement. The fertilizer granulation line can improve the fertilizer utilization and market competitiveness greatly. In the meanwhile, the fertilizer granulation line can reduce the impact to environment through closed production processes and modern control technology.

What’s the price of fertilizer granulation line?

Various factors influence fertilizer granulation line price, including the function of the capacity production, the degree of automation, the equipment and so on. And commonly, fertilizer granulation line price is usually at $100,000~$550,000.

-

Fertilizer pelletizing line for small or large size production.

If you have not too much for fertilizer production, then you can choose a small scale fertilizer production line. It can produce 5t fertilizers in an hour and is equipped with a full set of production equipment. And the small size granulation line price is at $110,000~$200,000. Besides, if you have large requirement for fertilizer, you’d better purchase a large size fertilizer granulation, which costs you $360,000~$500,000. On the one hand, it suits for large scale production. On the other hand, it can shorten your production period compared with small scale fertilizer production, which can improve working efficiency greatly.

-

Fertilizer granulation line with different levels of automation.

First of all, if you have enough budget, we suggest you buy a complete production line. And it will take you $150,000~$400,000. It not only can produce fertilizer quickly but also save the costs of labor for you. Because, it’s easy to operate and the whole process of production is fully automatic. In addition, it has a low cost for maintenance. We also provide you fertilizer granulation lines with a medium degree of automation that equipped with essential machines, such as automatic mixing, automatic granulating, and automatic metering.

To some extent, it can reduce human error in the operation process. Product quality and consistency are also guaranteed due to a more standardized and consistent production process. The price of middle level fertilizer production line is at $160,000~$200,000.

-

Choosing a customized serviced.

In addition to the 2 granulation line mentioned above, you can also purchase a fertilizer production line through customized services. And you only need to tell your requirements to our company. We can give you the best solution including the key machines like crushing machine, mixing machine, granulating machine, drying and cooling system. What’s more, we also provide installation and commissioning, staff training and after-sales service, etc.

In conclusion, when you want to purchase a fertilizer production, you should make a decision based on your materials and requirements.

What’s the application of fertilizer granulation line?

The fertilizer production line can be used for fertilizer production with various raw materials. It can produce organic fertilizer, NPK fertilizer, bio-organic fertilizer, and many other fertilizers. And the production process is different according to the difference of raw materials and machine used in fertilizer production. And the design of fertilizer granulation line is flexible that you can adjust your production process and formulas according to different raw materials and market demands. In addition, it’s helpful to guarantee the final product quality in the means of controlling temperature, humidity and other parameters.