Pan granulator, as a widely granule preparation equipment, is favored by enterprises for its simple structure, convenient operation, adaptability and other advantages. It forms spherical particles in the rotating disc through the material’s own bonding force or the addition of binder. Thus can realize the granulation process of the materials. And pan granulator price also varies a lot depends on variety of factors. Pan granulator price reflects the overall performance and value of the granulator, is also a key factor in the decision-making process of potential consumers.

What’s the working principle of disc granulator?

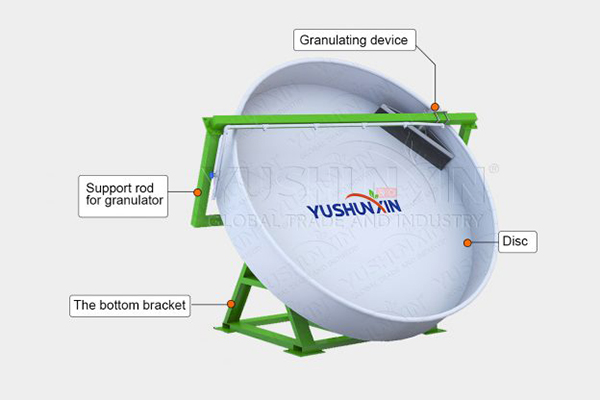

The working principle of disc granulator is based on the wet granulation process of materials. After adding appropriate amount of moisture or blinder in the materials inside the disk, the material gradually rolls and gathers under the action of gravity, centrifugal force and friction of the disk edge and form small spherical particles through the rotary movement of the disk. With the continuous rotation of the disk, these small particles are constantly superimposed on the new material, gradually increasing in the size and molding. In the meanwhile, you can adjust the inclination of the disc, the speed of rotation and the humidity to control the size of the particles and the quality of the molding. Eventually, the formed pellets are exported for subsequent drying and curing processes.

How to produce high quality fertilizer with disc granulator?

In order to produce high quality fertilizer with a pan granulation machine, you should pay attention to the following aspects. And it mainly includes the quality of raw materials, moisture content, equipment maintenance, process optimization and product quality inspection. And if you want to produce high quality fertilize, here are the methods for your reference.

These are the major steps of granulation, pay more attention at every step you can produce high quality fertilizers.

Where can you buy an economic pan granulating machine?

There are many manufacturers selling pan granulator and you can purchase a disc granulator machine from local machinery suppliers or shopping online. Besides, choosing us is a good choice because we can provided you our best services.

Firstly, our product has a high quality that you can use them work for you for years long and you just need to change several parts, which costs you little to maintain the machine.

In addition, as a source factory of granulation we can offer you the best machine you want with a lower price. And there is no need for you to pay for additional fees. That means you can buy a fully functions with not too much money from our company.

What’s more, we also provide you customized services and we can offer you the best solution according to your needs. That you can obtain the machine you want exactly. In a word, we are the best choice for your disc granulation machine purchase.