Converting animal dung into organic fertilizer can bring you economic income. On February 17, 2025, a Vietnamese customer sent a query from the website. “We want to understand the standard process & area needed – Budgetary cost for Organic Fertilizer Plant (10 T/H ). The main material is cow manure and goat dung. After communication, we provided a set of 10 T/H organic fertilizer machine to him. The following are details of our communication.

Can you provide low cost organic fertilizer production using animal manure as raw material?

The customer from Vietnam want to use goat dung and cow manure as organic fertilizer at a low price. Generally speaking, there are three types of organic fertilizer to choose to produce for fertilizer suppliers: liquid, powder, and granulated ones. If you want to produce organic fertilizer at a low investment, we advise you to set up a 10 t/h organic powdered fertilizer production line. The process of making fertilizer powder consists of dehydrating animal manure, compost, crushing, screening, and packaging the final organic fertilizer. The cost to start a 10 t/h organic fertilizer plant is about $6,8567.

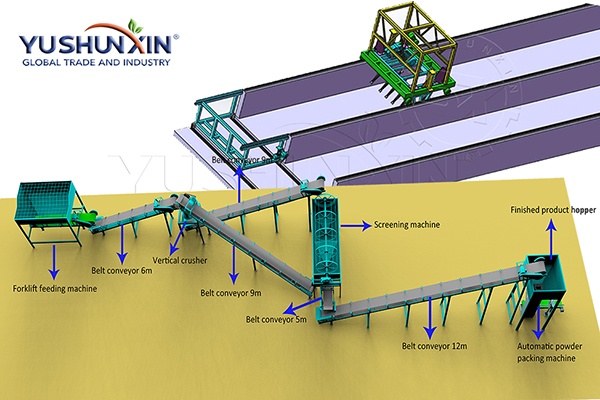

What equipment are needed for 10 t/h organic fertilizer manufacturing plant?

Manure dewatering machine

The moisture content of fresh manure is too high to compost directly. So, at the beginning of making organic fertilizer, you should dehydrate the cow and goat manure. The solid-liquid machine will be a great help. It removes fecal moisture through screw extrusion. After dewatering, the moisture content of animal dung can be reduced to 25%.

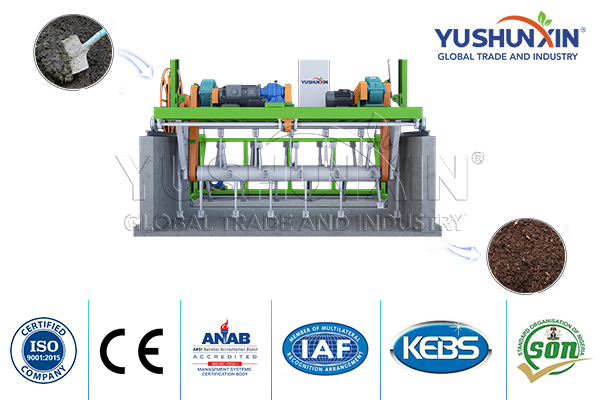

Groove type composting machine:

The trough composter is very suitable for indoor farms such as cow stables and sheep stables. For the 10 t/h manure fertilizer making line, the SXCF-4000 groove type compost turner is a good choice. Because it can turn organic compost with a width of about 4000mm and a depth of about 800mm.

With its help, you can regularly turn the manure compost to adjust its temperature, humidity, oxygen, etc. Moreover, we can customize the spraying device to the machine, so you can add water or fermentation agents.

Compost shredder

The new SXFLF-1000 crusher is the most cost-effective manure organic compost crushing equipment currently available. It can not only grind the manure compost into powder, but also crush other materials, such as fungus residue, sludge, etc. By setting its parameters, you can get the ideal size of organic fertilizer. In addition, its blades are made of special materials, which are corrosion-resistant. So, it can crush high-moisture organic fertilizer raw materials.

Drum screening machine

In a set of 10 t/h organic fertilizer machines, there are two benefits of using a drum screener. On the one hand, It can screen out impurities in organic compost, such as stones, cigarette butts, etc. On the other hand, it can screen out large-sized and unqualified organic fertilizers. The screening machine can ensure the final fertilizer’s quality and purity.

Double-bucket fertilizer bagging machine:

For large-scale fertilizer plant, We have equipped a double-bucket powder packaging machine. In order to prevent the organic fertilizer powder discharge from clogging, we increase the steepness of inlet using gravity to reduce friction . It can speed up the packaging of powdered bio – fertilizers.

In addition to the basic organic fertilizer machines, we are also equipped with forklift feeders, belt conveyors and bucket elevators, etc. Under the remote guidance of YUSHUNXIN staff, this 10 t/h organic fertilizer production line was successfully operated in Vietnam.

How much land area required for 10 t/h organic fertilizer making?

The 10 t/h organic fertilizer manufacturing line covers less area about 3,500 ㎡. It includes 4 parts: materials area, fermentation area, organic fertilizer machine working area, final fertilizer product area. We advise the customer in Vietnam to build a workshop with a height of 6 m in the 10 t/h fertilizer factory. This can effectively reduce the wear of organic fertilizer machine and prolong its service life. If you have requirements for the area, contact us! We will make reasonable plans for you to the maximum extent.

The above is the details of our communication with Vietnamese customers. Besides, we also provide you with chicken manure fertilizer making line, compound fertilizer, and liquid fertilizer production equipment. Welcome to consult!