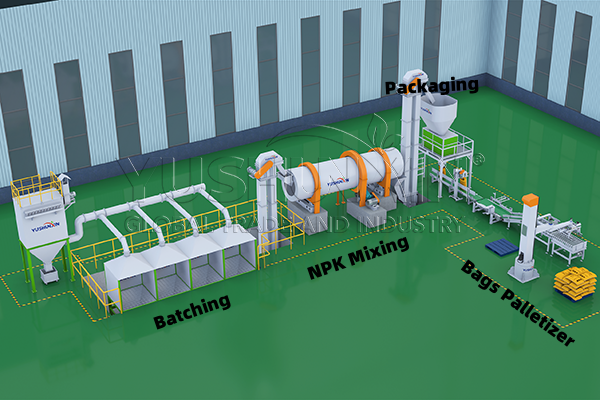

For most fertilizer manufacturers, start a bulk blending fertilizer plant is a cost-effective business. Because the whole process of bulk blend fertilizer manufacturing is simple, only needs three step: batching, mixing, packaging. For this, you can consult the professional fertilizer machine supplier. For example,YUSHUNXIN. On January 7, 2025, a customer from Zimbabwe inquired about 10 T/H fertilizer blending plant setup. The following are the specific details of our communication.

Is there a turnkey solution for 10 T/H fertilizer blending plant setup?

The customer from Zimbabwe wanted to start a fertilizer mixing plant with a capacity of 10 tons per hour. Their raw material are: Granular Urea, Granular sulphur, black urea, MOP, KNO3, gypsum filler, SOP… So we recommended him a series of 10 t/h fertilizer blending equipment. They are: dynamic feeders, BB fertilizer mixer, double-bucket and conveyor. It is simple, but can help you to make high-quality compound fertilizer. In order to prevent the raw materials from being difficult to mix due to large density differences, we have designed anti-segregation structures of the BB mixing machine. For example, the bottom discharge port has no dead angle and the slow discharge design can avoid stratification.

Can you provide the high-precision batching system for fertilizer blending?

The customers have clear ratios for raw material mixing in fertilizer blending, and require high precision. For this reason, our dynamic batching machine plays a big role. YUSHUNXIN‘s dynamic batching system uses an electronic belt scale as a metering system. The host has PID adjustment and alarm functions, with an accuracy error of ≤±0.5%. It can not only realize the control of a warehouse, but also batch continuously

Is the 10 t/h fertilizer mixng system highly automated?

The customer wanted a highly automated 10 t/h fertilizer blending system to reduce labor costs,especially in the packaging process. Don’t worry, YUSHUNXIN configured 3 control cabinets for the 10 t/h fertilizer mixing plant. To ensure the accuracy of mixing raw material, we prepared a separate PLC controller for the automatic dynamic batching system. Also, there is an independent controller in the automatic fertilizer machine. Our packaging machine can automatically weigh the ingredients, and the system’s quantitative accuracy is 0.2%. The remaining control cabinets can control the operation of the entire blending fertilizer production line.

What is the price of 10T/H fertilizer blending plant?

Then, like most fertilizer manufacturer, the budget of fertilizer plant is what this customer cares about most. The Zimbabwe’s customer inquired about the cost of 10 T/H blend fertilizer production line. As a well-known fertilizer machine supplier, we insist on treating customer with sincerity and serving them with the most preferential prices. Generally speaking, the 10 t/h fertilizer blending line is sold for about $130,000. However, YUSHUNXIN will launch 5%-10% discount from time to time. The cost is not fixed, it will vary with design, capacity and other requirement. Welcome to consult!

Is it possible to scale up the fertilizer mixing system in the future?

Of course. In addition to the 10-ton mixed fertilizer production business solution, we can also provide you with free upgrade guidance to expand your fertilizer business. In addition to adding fertilizer blending systems and bb fertilizer mixers, YUSHUNXIN can also provide you with a drum fertilizer mixing system. With its help, you can produce 30-40 tons of mixed fertilizer per hour.

The above are the details of our communication with the Zimbabwe customer about the 10 tons/ hour fertilizer blending plant setup. In additional, YUSHUNXIN will provide you with other fertilizer production equipment and business plans, welcome to consult!